All PRODUCTS

-

Read More

Handy&Wireless Thermometer (KTYPE)

Handy&Wireless Thermometer (KTYPE)Handy&Wireless Thermometer (KTYPE)

Handy & Wireless Thermometer

Application : Copper , Aluminium , Zinc , non ferro alloy melt

A、Wireless Thermometer AT -150 [ simple ] , ATW-150 [ wireless ]

Size:W 89*D 155*H 175 m/m

(1) New model TFT-LCD liquid crystal display

(2) Panel displays the previous 4 temperature records.

(3) Excessive expected temperature alarm.

(4) Rapid measurement within 5-6 seconds to peak hold.

(5) Determine whether peak temperature is between the expected range by varying the figure color .

(6) The thermometer is lightweight and compacted design

(7) Automatic peak hold with simultaneous buzzer sound alarm as well as the figure blinking.

(8) Automatic power off to avoid non-essential power consumption.

(9) Power status indication and low voltage alert.

(10) Battery charged quickly and lower power consumption .

(11) USB interface to upload the missing data to recorder.

(12) Thermocouple K-Type (0-1370 ℃).

Model : ATW -150 [ wireless ] attached the extra functions as the belows .

(13) 10 channels available [0-9] for setting the thermometer.

(14) Wireless transmission distance can reach as far as 100M.

(15) The specific marked button mounted at the side wall.

(16) Switch for melt code to list melt information .

B、Temperature Display ATD-300D

Size:W 490*D 70*H 150 m/m

(1) The large display (100m/m LED) can clearly show the temperature data.

(2) To work with 10 thermometers by different channels [0-9].

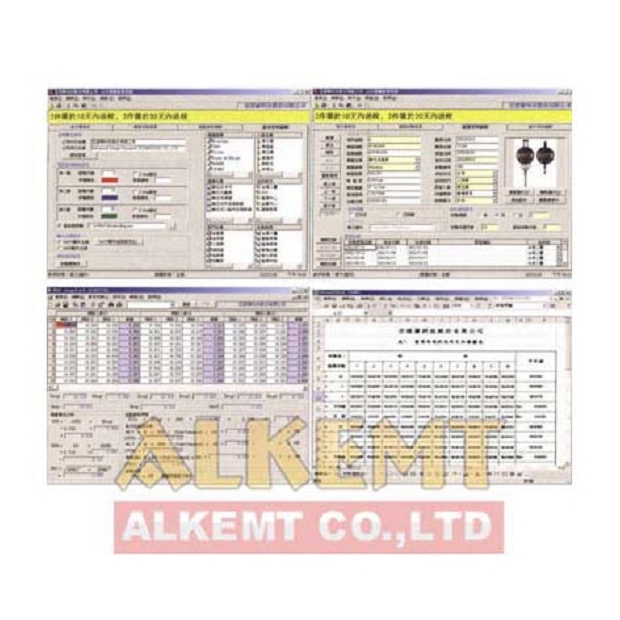

C、Temperature Recorder ATR-250D

Size:W 232*D 200*H 55 m/m

(1) Real time temperature display.

(2) Instant display for the melt code.

(3) Historical data and trend chart storage, query, and printing.

(4) Peak temperature display in ℃ or ℉.

(5) Synchronous loading and recording of peak temperature

Time, thermometer ID, molten melt, casting name, and mark indication.

(6) Set up the expected temperature range for the melt.

(7) Temperature diagram for checking the abnormal temperature.

(8) External monitor and printer is available to connect .

(9) The dust-proof design for recorder case . -

Read More

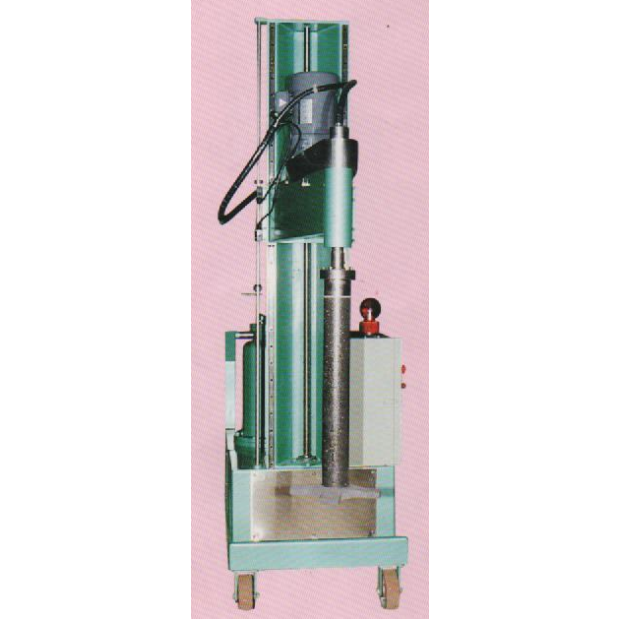

Flux Feeder

Flux FeederFlux Feeder

A. Summary:

In recent years, for degasification and deslagging, casting industry mostly uses refining agent and dissolving metal for mixing and stirring, but the effect of refining agent has never been exerted 100%, therefore, our company has been researching on this issue and made development: The equipment that can carry out adding and stirring steps with simple and convenient operation to improve its actual effect, this is the “Flux Feeder”. The use of such equipment can not only solve the similar problems mentioned above, but also reduce the usage amount of refining agent; its effect is sufficiently exerted for the improvement of operation environment etc.

B. Characteristic and specification:

Stability of the flow of refining agent, its quantitative difference is within 5%.

Simple operation, uniform handling, simple and easy for user to learn to operate.

Simple structure, easy for maintenance, it can be used for a long term with regular inspection and maintenance, besides, it is of corrosion resistance.

With steel wheel, convenient for move; besides, after confirming the placing location, it’s not easy to be deviated after fixing the steel wheel.

Specification:

Storage tank capacity

60ℓ

Flow of refining agent

~1,500g/min

Nitrogen

2~7kg/cm2 , 350N ℓ/min

Gas (N2) operating pressure

~1.9kg/cm2

Motor

variable speed 60w

Power supply

50/60Hz ,1φ AC220V

Machinery

Weight

about 170kg

Dimension

800x535x1200 (Length x width x height) mm

Accessory: 1. Nitrogen high-pressure rubber hose 5/16φx5M